Food – Chocolate Processing

With RheoStream® automatic control of chocolate rheology, you get the viscosity of chocolate right.

We all love chocolate – the crack of ice cream covered in chocolate, a milk chocolate bar’s sweetness, or a chocolate-based drink.

For every use of chocolate, the product that a consumer enjoys must live up to certain expectations of what we know chocolate to be. Some chocolates must cover ice cream in a uniform layer. Some must fill a mold to form a perfect glossy surface.

How Chocolate Is Processed

Each type of chocolate has its recipe and its precise way of being manufactured. One of the determining factors in making the perfect chocolate every time is to control the product’s consistency or rheology. Controlling chocolate’s rheology is done when the chocolate is in a liquid state, typically at 40°C or higher.

The critical process steps that define the rheology of chocolate are milling, mixing, and conching. In these steps, cocoa liquid or powder, cocoa fats, sugar, milk (powder), and other ingredients are mixed, heated, and ground. The chocolate mass starts as a powder, is combined to form a paste, and ends as a liquid at high temperature – this is the place to check if the rheology is right.

Why Is Rheology Important In Chocolate Processing?

And what is “right rheology”? Chocolate is a non-Newtonian liquid (what is that? Click here). It gets thinner with higher shear, “faster movement.” This means that the viscosity must be controlled across a range of movement rates – how thick is it at low speed, and how thin is it at higher speed? Moreover, it must have well-defined yield stress results.

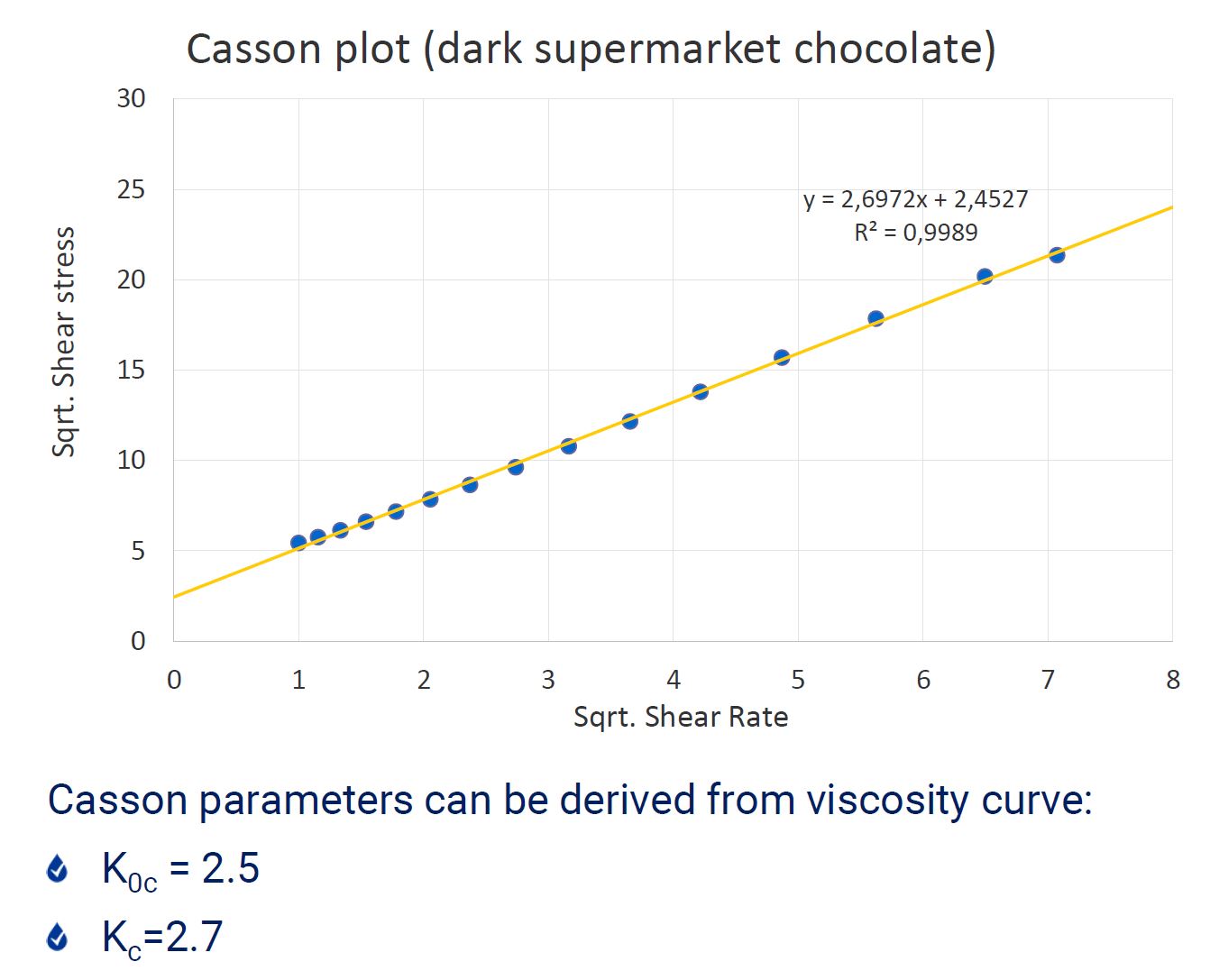

Chocolate makers measure these properties in laboratory rheometers, and they follow a standardized procedure for how they handle and measure the chocolate. This procedure includes taking a sample in the production line, taking it to the lab, preheating or cooling the chocolate, and measuring it at 40°C, typically at shear rates from about 1-5 [1/s] and up to 50-100 [1/s]. The measurement generates a complex set of data. To extract the chocolate’s key characteristics requires that the data be fitted to a simple mathematical model, usually a model named “Casson”. Using the Casson model, the entire viscosity behavior of the chocolate can be summarized in two numbers: The Casson yield value (“what is the force required to start the flow of the chocolate?”) and the Casson plastic viscosity (a “shear thickening factor”).

We asked the question “what is right rheology?” – for each quality and type of chocolate the two values give the answer – the Casson yield value and the Casson plastic viscosity must be within a defined minimum and maximum limit.

And what if the rheology is not right? The chocolate may not flow to cover the ice cream well, or it may solidify in a mold leaving air bubbles on the surface. These errors must be corrected. It is possible to add more fat/butter to make it thinner, but if it is too thin already, the producer may have to recycle the entire batch and, for instance, mix it in with a thicker batch.

Rheology is, for a large part, determined in the concher. The ingredients that can modify the rheology are added here, particularly emulsifiers such as lecithin (E322) or PGPR (E476). However, because it takes time to measure rheology in the lab, it is not possible to automatically adjust and optimize the quantity of fats and emulsifiers added in the concher – if the rheology is not right, it must be corrected downstream or even reprocessed.

Making Better Chocolate With RheoStream

RheoStream® automatic control of chocolate rheology is the obvious answer – real-time information about the Casson yield value and the Casson plastic viscosity makes it possible to adjust the process and make sure the chocolate produced is always of the right quality. We say, “Rheology on track.”

How does it work? RheoStream takes in a sample, cools it to precisely 40°C, and produces a viscosity curve, e.g., 2-50 [1/s]. It calculates the Casson yield value and the Casson plastic viscosity and displays these values on a graph. RheoStream also exports the values to the factory control system, making it possible to program an automatic correction of the process. With RheoStream, each measurement typically takes 2-3 minutes, then an updated set of values is ready.

The RheoStream instrument can be mounted directly on the concher, making it possible to adjust ingredient dosage and concher settings immediately. Or it may be mounted further downstream, merely replacing the current manual and time-consuming laboratory methods — the most considerable benefits are gained by having real-time information directly in the concher.

Imagine never having to wait for the manual analysis and never recycling a batch because it was too thin!

Fluidan ApS

Company register: DK36392355

Authorized representatives: Anders L. Østergård (CEO) or Fridolin Okkels (CTO) and Steen Hoff (Chairman of Board)

Privacy

Our privacy policy

Address

Diplomvej 381

2800 Kgs. Lyngby

Denmark