Fluidan’s Unique Technology

RheoStream® is a fully automated capillary rheometer in a box!

A precision pump in the instrument controls the sample flow rate as it passes through the capillary.

RheoStream measures the viscosity profile typically every 1-2 minutes: A sample automatically flows into the instrument, and it is being measured in a sequence of steps. When done, a new sample is taken – every sample is 5 ml.

Unlike any other process rheometer RheoStream takes full control of the sample. That gives important benefits:

- The sample temperature is controlled to the desired level

- The viscosity is measured across a controlled range of shear rates

The output from RheoStream is the viscosity at 3 shear rates. Or you can get the parameters from a model of the viscosity curve (Bingham, Casson, etc.).

Read all about RheoStream

Download our brochure to uncover precision’s secrets!

Discover how our revolutionary product works, installation tips, interfaces, unrivalled precision, and detailed specifications.

This is How RheoStream® Works

By following the numbers on the picture (right), you can follow the progress of a measurement:

① A sample is drawn from process equipment

② The syringe pump controls flow rates in pulses ③

④ A preheater/cooler ensures a steady temperature of the measurement

⑤ The liquid flows through a thin tube (capillary)

⑥ A pressure difference (ΔP) is measured for each pulse

⑦ The instrument computer converts pressure signals into viscosity values

⑧ Displays results on the user interface

⑨ Spent sample is collected as waste

Rheology basics

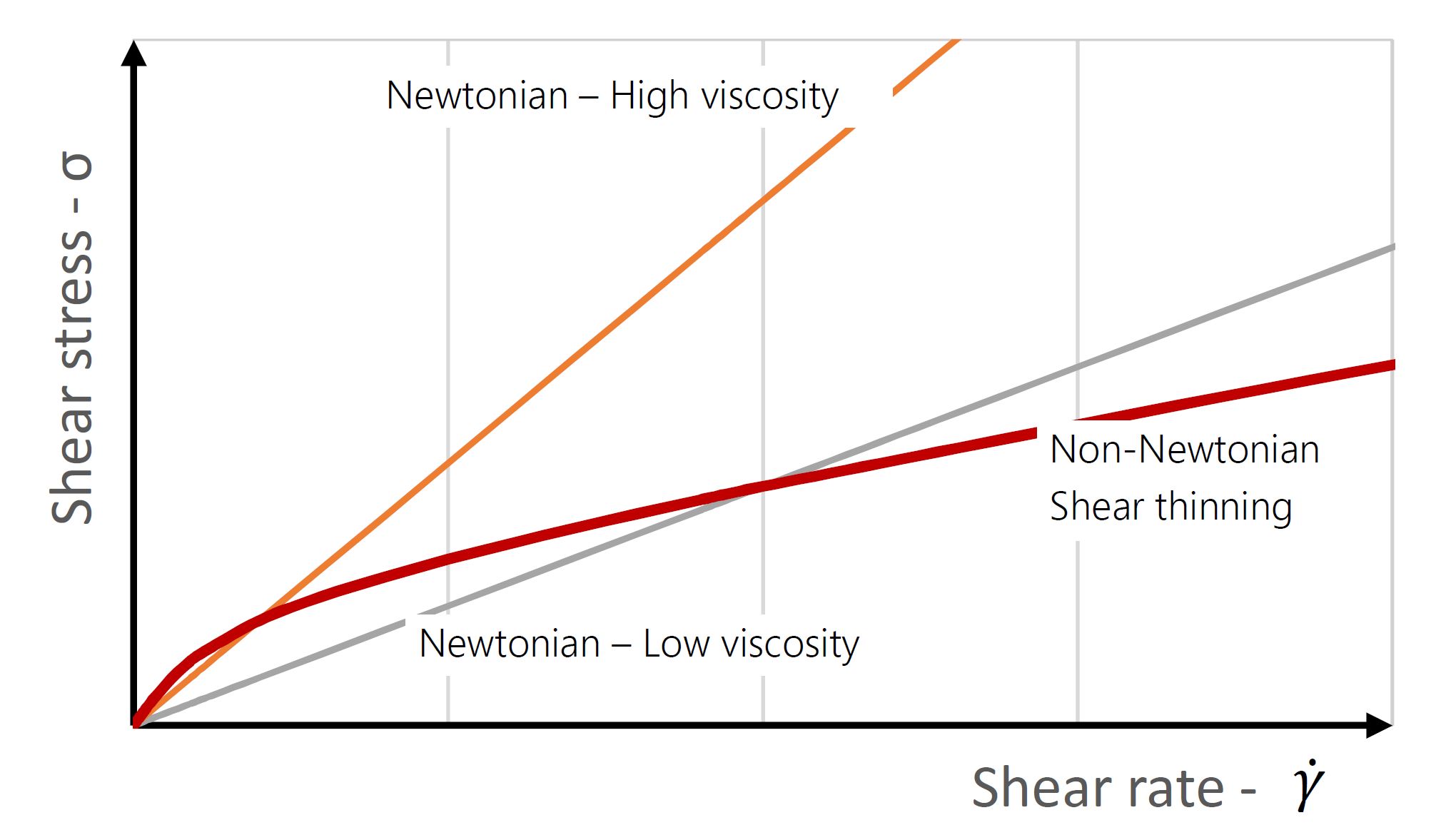

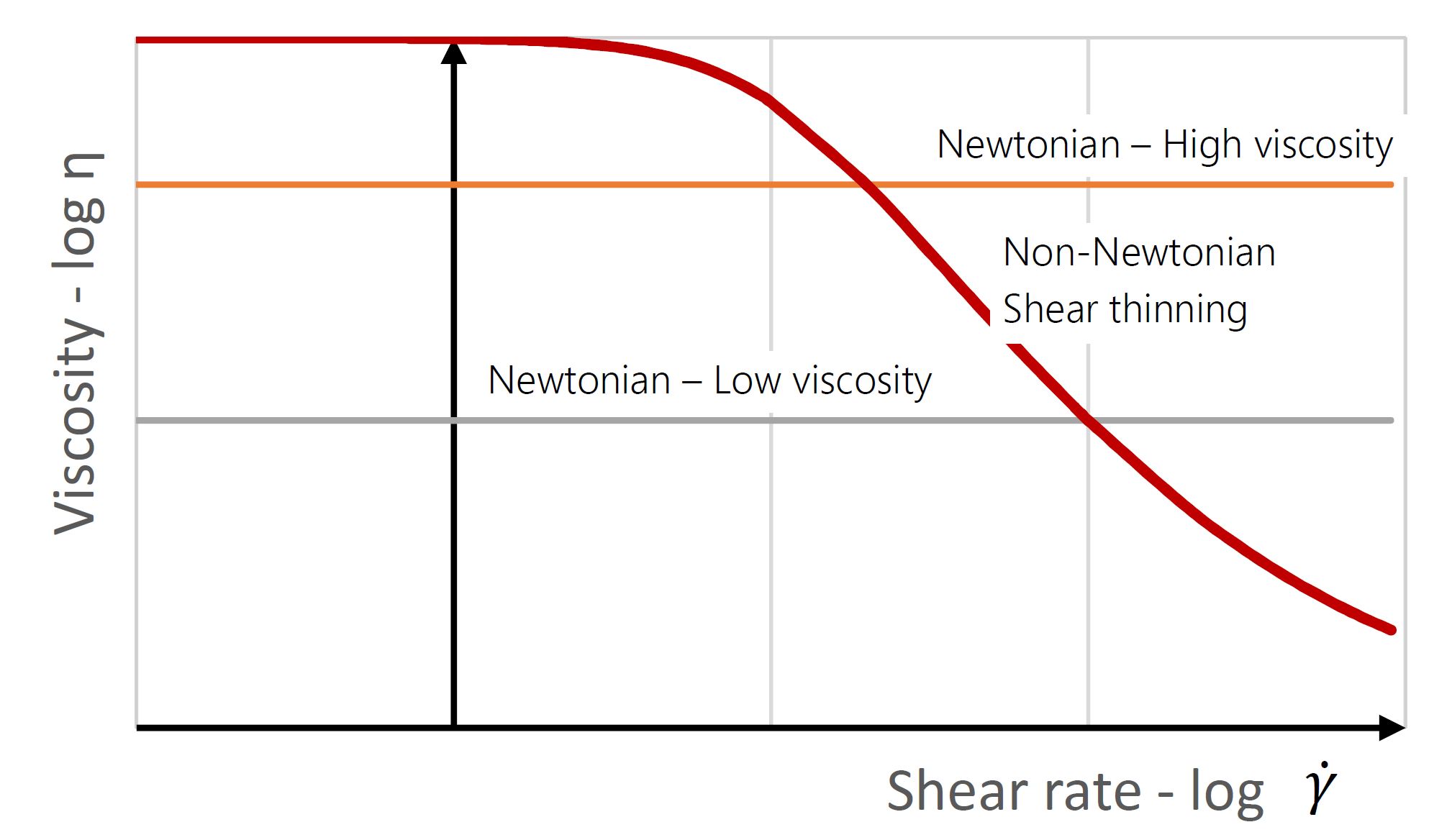

Liquids are categorized as Newtonian or non-Newtonian.

Newtonian liquids have constant viscosity across shear rates, non-Newtonian do not.

What does that mean?

Shear rate is the rate of deformation of the liquid. Imagine that you drag a boat through the liquid – in a thin liquid the force required is less than in a thick liquid. And the faster you drag the boat (= the higher the shear rate) the more force is required. In rheology the force is expressed as shear stress (unit is pressure, Pascal) and the speed is expressed as shear rate (unit is reciprocal seconds, /s).

“flow curve”. Measuring shear stress and viscosity across a range of shear rates is called “viscometry”.

In a Newtonian liquid the force required is proportional to the speed – the ratio between shear stress and shear rate is the viscosity (unit is Pa·s).

Examples of Newtonian liquids are water, oil and honey, going from thin to thick, or from low to high viscosity.

Shear Thinning Liquids

Non-Newtonian liquids do not behave in the same way. It does get harder to drag the boat when you go faster, but not proportionally. Most thick liquids are shear thinning, meaning that it gets relatively easier as shear rate is increased – the viscosity drops as shear rate is increased. Some, more rare cases exist, when viscosity is increasing with shear rate.

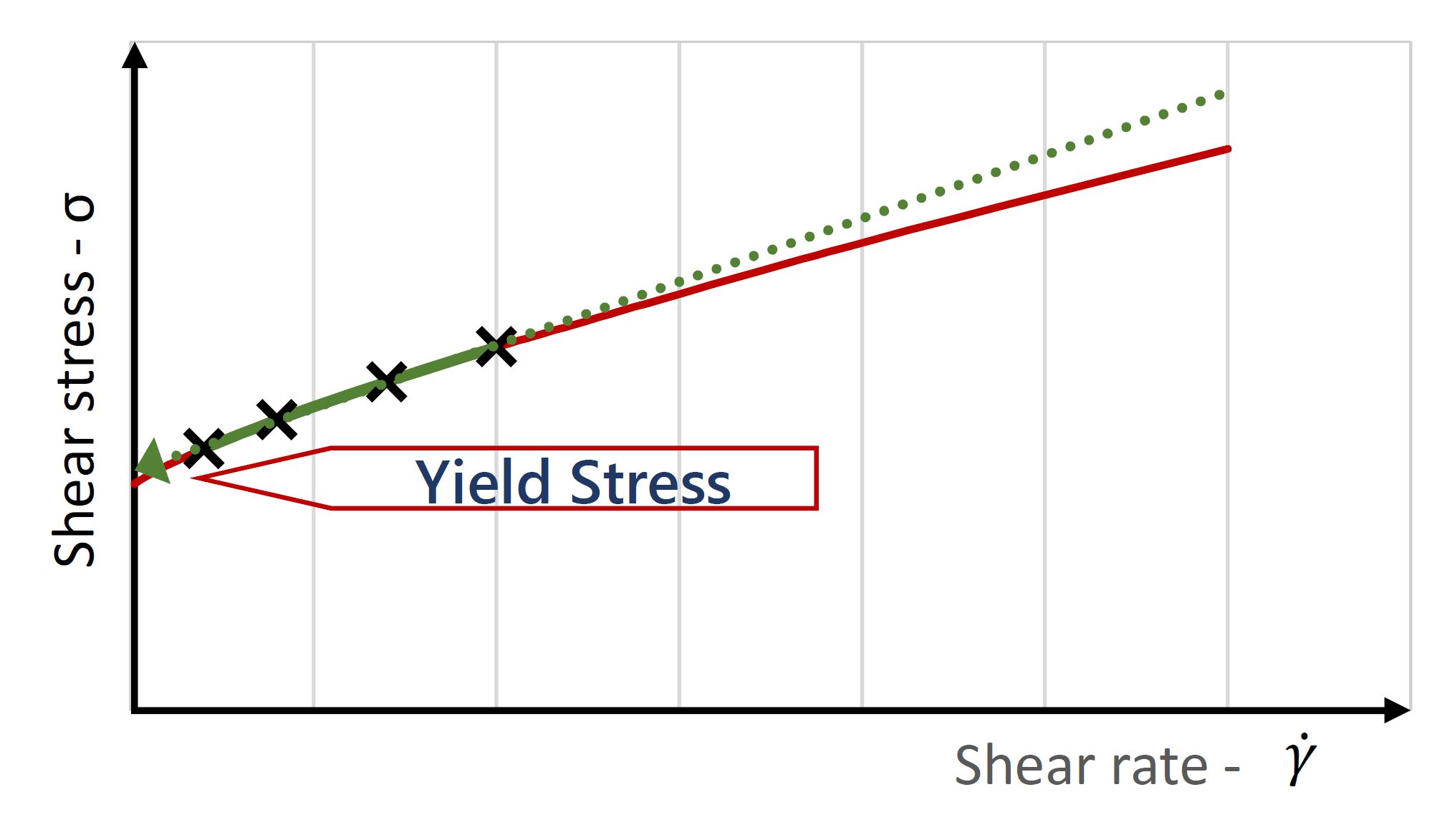

Why is this important for process control?

However, even if the viscosity at the chosen shear rate is constant and remains within the control range, it may represent very different liquids as seen in the figure: Three liquids, measured at a given shear rate have same shear stress and viscosity, but below and above this point they are very different.

In contrast, measuring with RheoStream will provide shear stress and viscosity values across a range, making it possible to differentiate the three liquids clearly.

Yield Stress Liquids

Many non-Newtonian liquids are also characterized by having Yield Stress. Yield stress means that when an increasing force is applied, the liquid does not start flowing until a certain threshold is surpassed. Or, in the example with the boat, you need to overcome a certain drag in the boat, before it stars moving.

The same approach works with RheoStream – points on a flow curve are fitted to a model, giving a measure of yield stress (see also Keeping a coating process on track)

Fluidan ApS

Company register: DK36392355

Authorized representatives: Anders L. Østergård (CEO) or Fridolin Okkels (CTO) and Steen Hoff (Chairman of Board)

Privacy

Our privacy policy

Address

Diplomvej 381

2800 Kgs. Lyngby

Denmark