Liquid Laundry Detergents

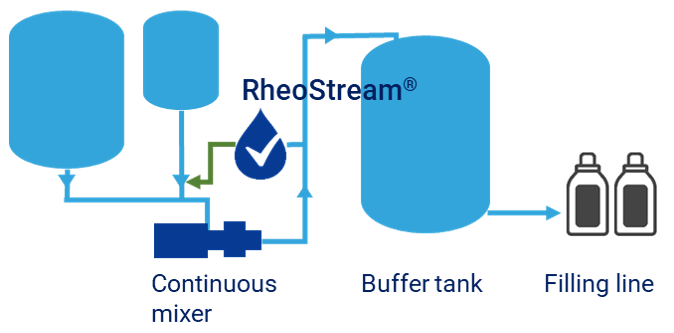

In the manufacture of liquid laundry detergents RheoStream® can be installed downstream of continuous mixing, to secure that critical rheology is kept on track.

Liquid laundry detergents are very high- volume products, often made in continuous operation, dosing a carefully balanced set of ingredients and mixing in a dynamic mixer.

Very similar processes are used for other liquid cleaning products, e.g., hand dishwash and fabric conditioners.

Some liquid detergents are quite sophisticated formulations forming structured liquids. The liquids are gel-like viscoelastic “solids”, with a certain (low) yield stress allowing to keep solids in suspension.

Regardless of how well the formula is composed, occasionally the process may go off-spec. Maybe the quality of an ingredient is variable, the dosing may get out of calibration or the mixing may not create the desired structure of the liquid.

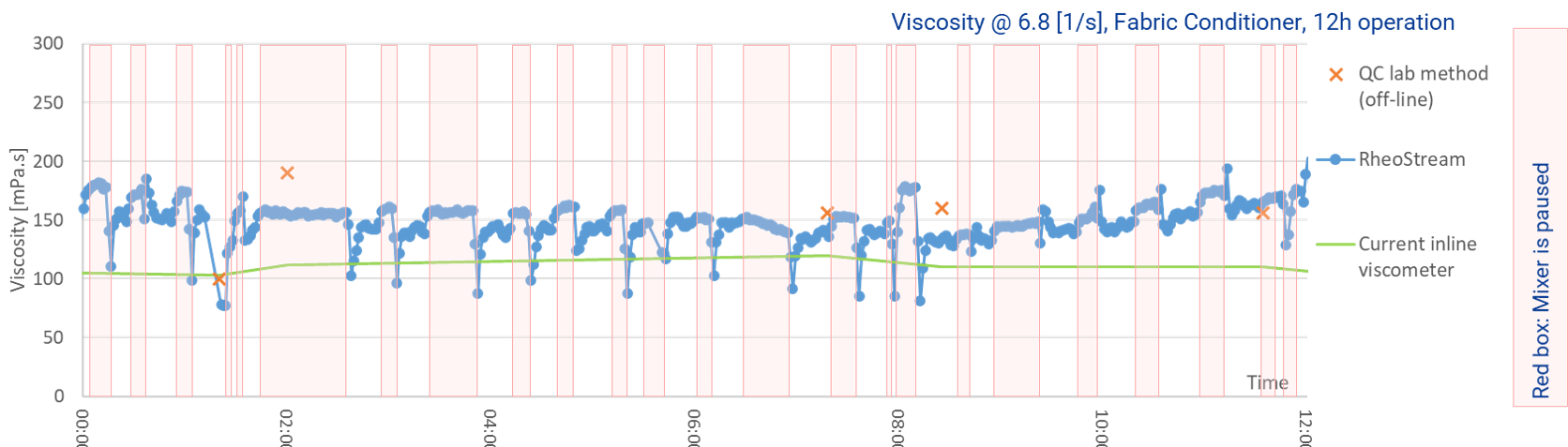

In a short time, a large volume of off-spec material may be produced. If the rheology is only monitored by taking samples of the finished product at intervals, the factory may have to re-work significant volumes of detergent. Typically, this occupies the main production line making it unproductive for some time. The factory output becomes unpredictable and the supply chain is upset.

Fluidan recommends installing RheoStream® downstream of the mixer and to develop a feedback loop to the ingredient dosing and mixing system. This may require that the production is monitored for some time (weeks) to develop sufficient experience to set up the optimal regulation loops.

RheoStream will continuously – e.g. every 2 minutes – read out key characteristics, such as key points on the viscosity curve (viscosity versus shear rate). The flow curve of liquid detergents may often be modelled with the Hershel-Bulkley model, and RheoStream can then read out the key characteristics of this curve every 2 minutes, including an apparent yield stress of the liquid.

Some mixing processes result in bubble formation in the soap, laundry or cleaning product being manufactured. RheoStream can measure on liquids with some bubbles, but the viscosity of the liquid may be influenced by bubbles. Very small bubbles will normally make the liquid thicker than a similar sample that has been de-bubbled. This will be registered by any precise viscometer or rheometer and is not a “fault” of the instrument, but a matter of actual viscosity behaviour. In such cases it may be considered to implement a de-bubbling device based on filtration, ultrasound or centrifugation to prepare the samples for online measurements.

Fluidan ApS

Company register: DK36392355

Authorized representatives: Anders L. Østergård (CEO) or Fridolin Okkels (CTO) and Steen Hoff (Chairman of Board)

Privacy

Our privacy policy

Address

Diplomvej 381

2800 Kgs. Lyngby

Denmark