Henkel is a leading manufacturer of household care products in Europe. Henkel pursues an ambitious Industry 4.0 and digitalization strategy.

See more about that here: https://www.youtube.com/watch?v=rdhlxmzXL1E

or here: https://www.youtube.com/watch?v=Qwbps_13zn8

A part of this is the automation of manufacturing processes including the quality control analyses required to maintain the highest quality standards.

The online rheometer, RheoStream® offered by Fluidan is the only instrument designed to meet the requirements for control of the viscosity profile of liquids household care products

Now, Henkel decided to implement RheoStream in the main liquids production facility in Vienna.

The decision comes after a thorough testing in a factory trial read here

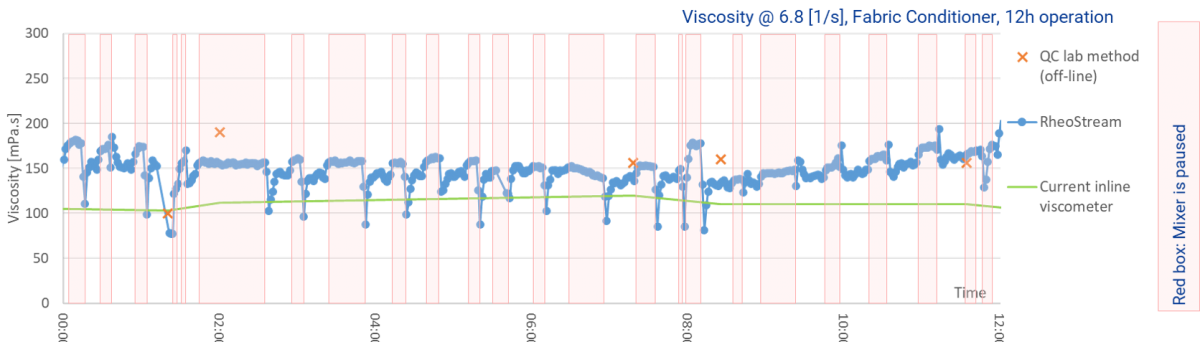

RheoStream gives a completely new level of insight into the process. With manual viscosity control in an off-line laboratory, it is not possible to track the actual fluctuations in viscosity. Over time, on average, the product may be fine, but RheoStream shows how small process variations has a significant impact on the actual viscosity, and this knowledge can be turned into even better control.

Fluidan offers two ways of interfacing to the factory data and control system (e.g. a SCADA system) – either a fully digital communication with the OPC-UA protocol, or a PLC-based analog and digital signal sending a 4-20mA signal.

Moreover, Fluidan also offers a mobile internet based IoT connection, to support and update the software remotely. With this support, RheoStream will always perform at its best.

Fluidan is proud to supply to Henkel in Vienna – a highly professional and dedicated manufacturing operation – and now even better.

RheoStream® FC ready for shipping