What do Viscosity and Rheology Mean?

Viscosity is a measure of a fluid’s resistance to flow. So, yes, you probably want to measure the viscosity of your liquids in a production process. It is significant for understanding how the liquid is mixed and pumped in equipment such as mixing tanks, pipes, and pumps. And it is essential for how the final product appears – think of paint, a liquid detergent, or a beer: They all have different viscosity, and they should have. What about rheology, then, any reason to bother? Probably yes.

Is It Thin or Is It Thick? It Is Thick and Thin

Imagine that you stir a liquid in a bucket. In a thin liquid, the force required is less than in a thick liquid. The faster you stir, the more force is needed. In the measurement of viscosity, the speed of stirring is represented by the Shear rate. Shear rate is a measure of the rate of deformation of the liquid. The force you need to stir is represented by Shear stress. If you divide shear stress (the force needed) by the shear rate (the speed), you get viscosity. If the liquid is thick, you need a high force to get even a slow speed. The viscosity is high.

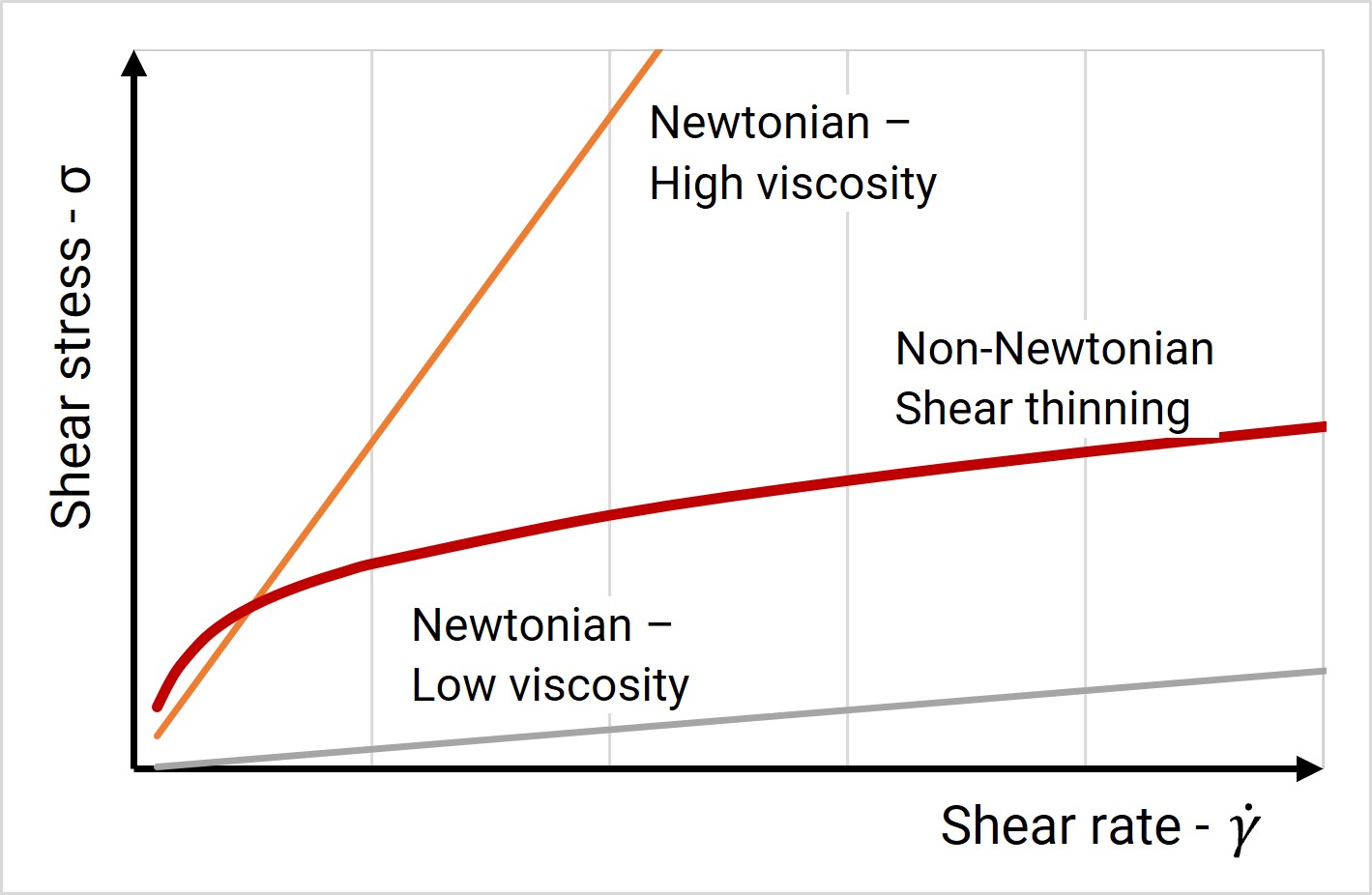

Next, you stir at different, increasing speeds and measure the force needed. Some liquids make twice the resistance at twice the speed. When you draw a curve, shear stress versus shear rate is a straight line, starting at zero. The line is relatively flat if the liquid is thin and steep if it is thick – see the grey and the yellow line in figure 1. Viscosity is the slope of these lines. If it is such a straight line, the liquid is called a Newtonian liquid. To measure the viscosity, you apply a shear rate and measure the corresponding shear stress. No matter if the shear rate (speed) is low or high, the line has the same slope, and the viscosity is the same at all speeds.

However, most thick liquids do not behave like that.

Newtonian or Non-Newtonian?

As you increase the speed, it does require more force, but not quite that much. It feels easier at a higher speed. The curve is the red one in figure 1. The curve is steep at the beginning (high viscosity) and flattens as the shear rate increases (lower viscosity). The liquid is thick at low speed and thin at high speed. If the curve is different from a straight line, the liquid is called non-Newtonian. In this case, getting thinner at higher shear, the liquid is “shear thinning.”

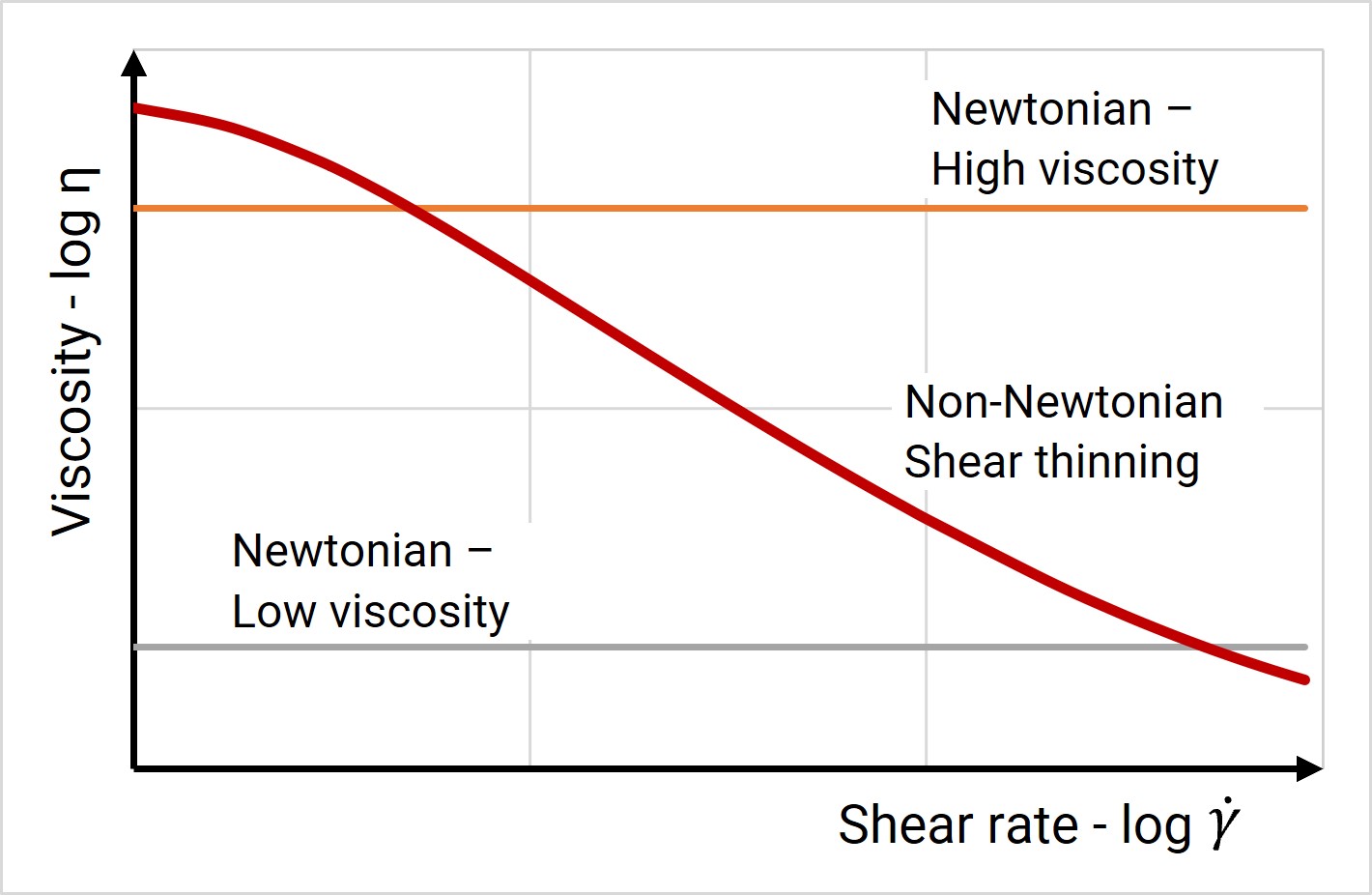

Newtonian liquids have the same viscosity at all shear rates, while a shear-thinning liquid gets thinner, as shown in figure 2, with the same three liquids as before.

Figure 1. Newtonian liquids: Shear stress increases proportionally to shear rate. Non-Newtonian: The shear stress increase is not linear.

Why Is Shear Rate Important For Process Control?

Today many companies have installed in-line viscometers for process control purposes. A viscometer measures the viscosity at one shear rate. With proper process control, the viscometer can help keep the viscosity at the right level. However, even if the viscosity at the chosen shear rate is constant and remains within the control range, it may still represent very different liquids, as seen in figure 3. Three liquids measured at a given shear rate have the same viscosity, but below and above this point, they are very different. A viscometer that only measures at one shear rate is only a good solution for Newtonian liquids.

Yield Stress Liquids

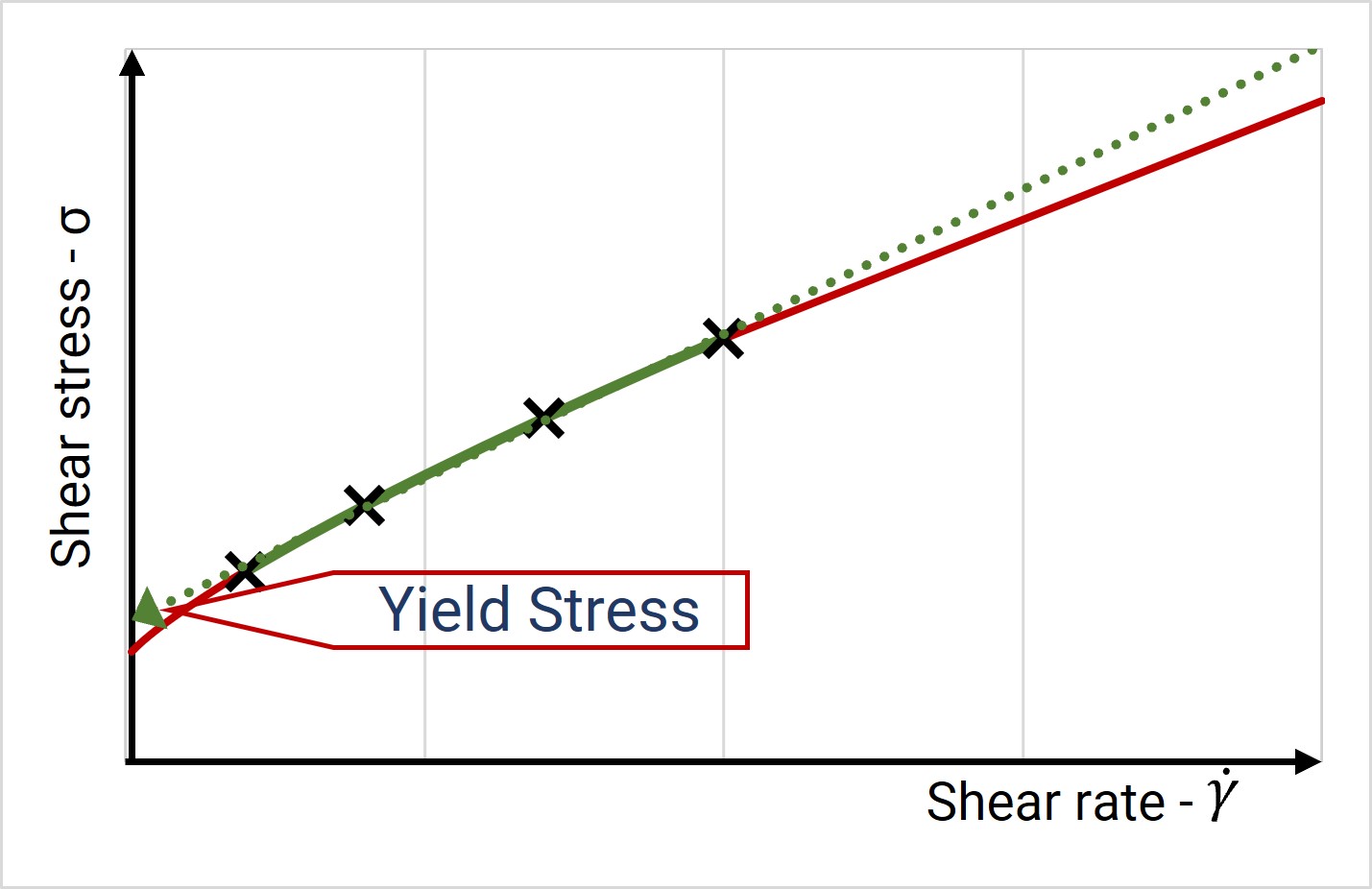

Many non-Newtonian liquids are also characterized by having Yield Stress. Yield stress means that when an increasing force is applied, the liquid only starts flowing after surpassing a certain threshold. In the example of stirring in a bucket, you need to overcome a specific force on the stirrer before it starts moving.

In classical laboratory rheology, there are many ways of measuring yield stress. One method is to create the same type of curves shown above, shear stress versus shear rate, and then find the shear stress at zero shear rate. That is found by extending the curve till it cuts the Shear stress axis, as shown in the figure 4.

RheoStream For Process Control Of Non-Newtonian Liquids

RheoStream is a process control rheometer. It measures a liquid’s viscosity at a range of shear rates—Read here how it works.

With RheoStream, you can tell the difference between the three liquids in figure 3. You set RheoStream to measure at three selected shear rates, in the low, the middle, and high ranges. The results are automatically given to you or your control system every 1-3 minutes.

RheoStream can also calculate if the shear stress curve goes through the zero point or if the liquid has a yield stress. RheoStream is set to measure at five shear rates, and a mathematical model will fit a curve to the points. The calculation can determine the yield stress and other key characteristics of the liquid rheology.

With RheoStream, you get a process rheometer that can give you all the critical parameters of a non-Newtonian liquid. Like no other instrument, it makes proper process control possible, and it takes process rheology to a new level.