Digitalization in the coatings industry takes many directions.

A top priority, is to manufacture at lowest cost and impact while maintaining a sharp quality and high flexibility when supplies and demands are changing.

This calls for better insight into the processes and it calls for full automation.

This week, Fluidan presented how to automate viscosity control in paint making.

Full Automation – Get Rid of The Last Manual Step in Paint Production

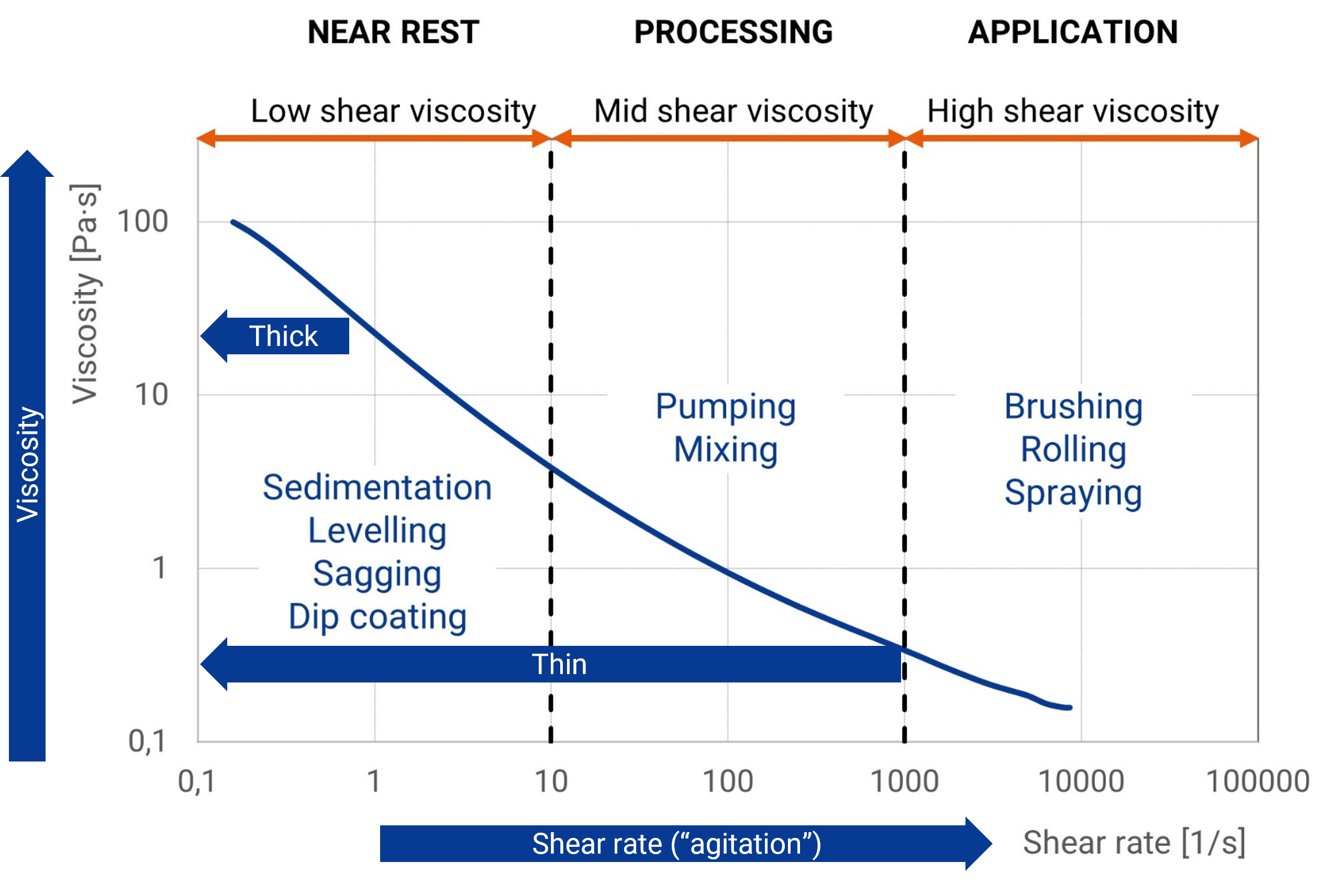

Viscosity of paint is not just one number, viscosity is both high and low, and must stay on that curve every time. This type of liquid is called shear thinning. Until now, no process instrument has been capable of measuring the profile of a shear thinning liquid like paint.

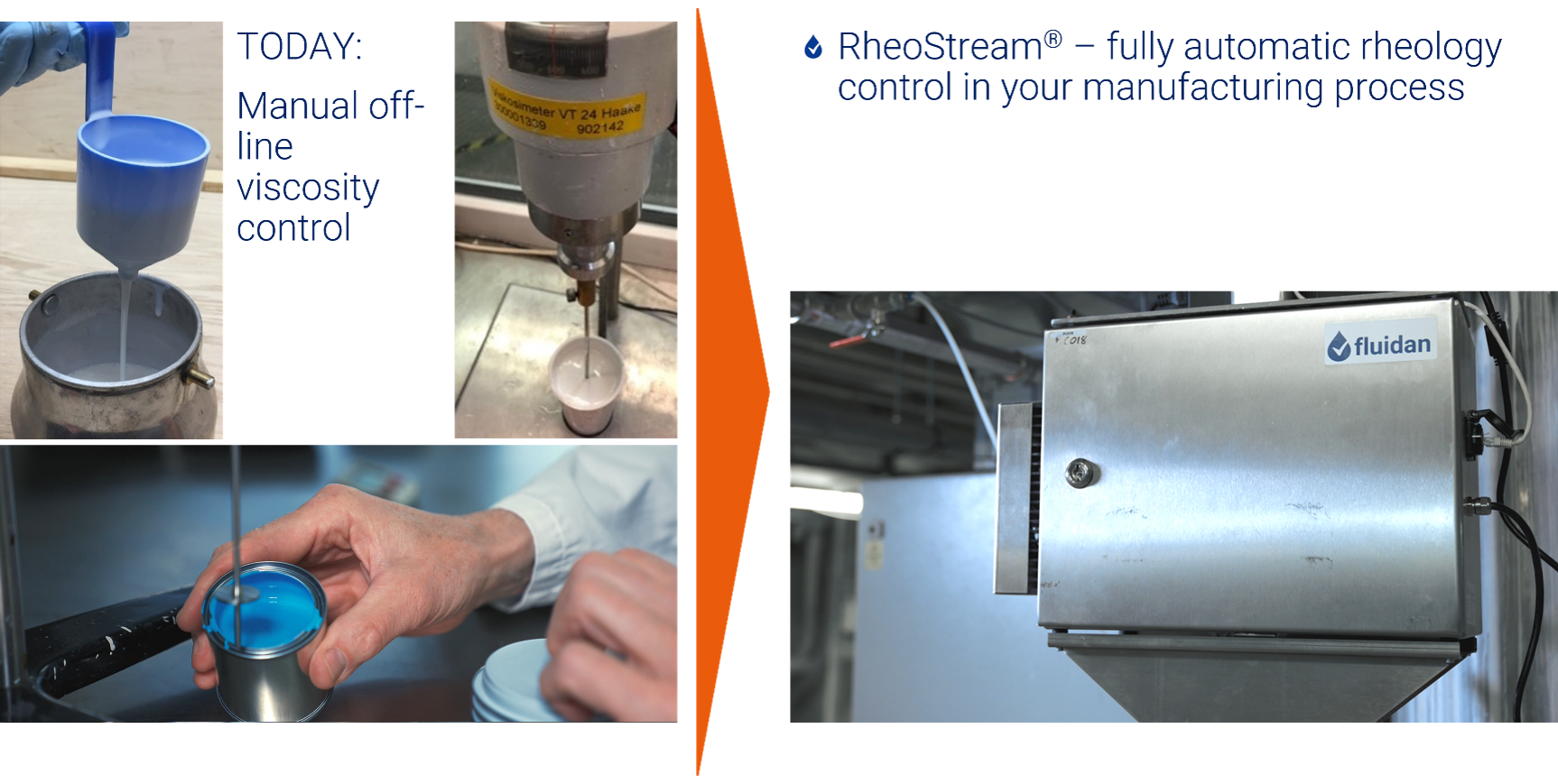

That is why, today, viscosity is measured by manually bringing a sample to an off-line instrument, for instance in the QC lab. Because it takes time and people the viscosity is only controlled once the paint has been fully mixed and transferred to a let-down tank.

If it should be possible to automate viscosity control, it will require that the viscosity is measured fast and automatically.

RheoStream® is such a process rheometer, and it thereby marks a new category of instruments.

That way the single most time-consuming operation can be automated, and simultaneously, the reason for more than 80% of all non-compliant paint batches can be eliminated.

European Coatings Show Conference 2021

This September we had all hoped to attend the European Coatings Show 2021 – but as it was cancelled, it was very positive that at least the Conference was successful, albeit in a virtual format.

Fluidan opened the session on Digitalization with the paper “Automated monitoring of viscosity in manufacture of coatings”.

Now the full presentation is available – just click the link above.

Presentation Q&A

During and after the presentation we received many good questions – maybe you have the same question after seeing the presentation, so here are the most important ones:

Q: In what range can viscosity be measured with RheoStream?

A: Generally, 0.1-20Pa∙s (if measured at 10 s-1) – and the shear rate range spans from 1.5-1000 s-1. Read more here.

Q: Is the fully automatic self-cleaning of RheoStream sufficient, or will it be necessary to do a more thorough manual cleaning in between?

A: The automatic cleaning is sufficient. It is typically programmed to run in-between batches or once every night.

Q: Can RheoStream calculate how much water or solvent is required for the viscosity adjustment?

A: No, RheoStream is a “viscosity sensor” giving fresh viscosity measurements every two minutes. But the knowledge of how much solvent to add is the expertise of the factory. Today, when a manual viscosity analysis is done, someone, for instance in the QC lab) decides how much solvent to add. This knowledge can be embedded in the control system and then the system will receive the viscosity information from RheoStream and will automatically instruct the automatic addition of water or solvent.

Q: Can RheoStream measure on a system with abrasive fillers?

A: yes, particles up to 1 mm will just flow through the capillary and will not disturb the measurement.

Thanks to the attendees!