Often, careful consideration of all available options has led to the conclusion that there is no way to measure the viscosity profile with a process analyzer reliably. The alternative is measuring the samples manually.

With RheoStream®, think again.

Does Your Process Viscosity Analyzer Tick All the Boxes?

It may be that you’ve never installed a process analyzer to keep track of viscosity in your process. Perhaps you did not find an instrument that could meet all your requirements? What are the requirements for the successful implementation of a process viscosity or process rheology analyzer?

First, the process analyzer must be reliable. The measurements must be correct and precise, and the instrument must be robust. Next is integrating the device into the factory control system: The data must be loaded into the system, making it possible to apply the measurements in an automatic control loop.

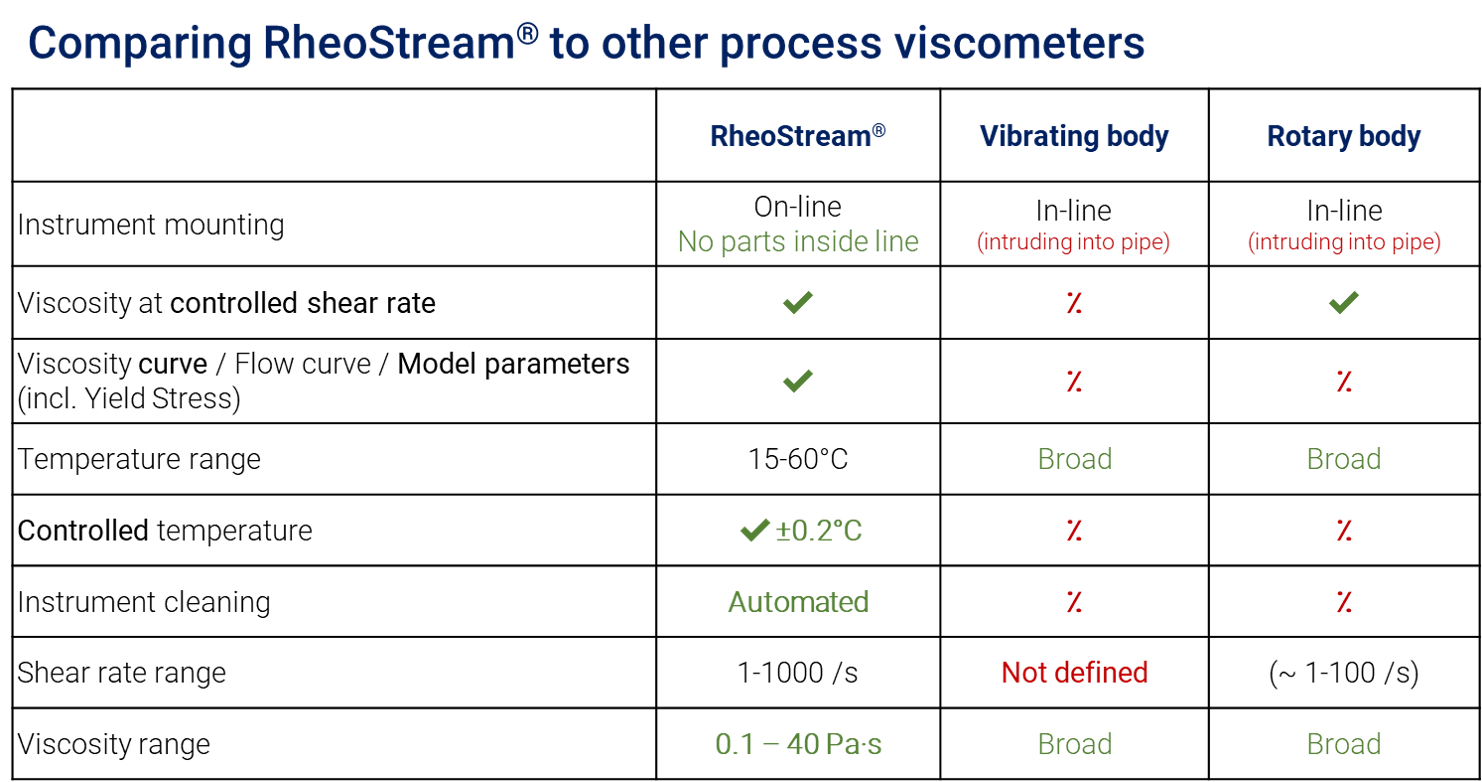

In any production of “thick liquids,” there is a need to keep track of the viscosity. Sometimes that is a relatively simple task, which is well performed by a range of inline viscometers. Still, if the liquid is Non-Newtonian, and the viscosity profile matters, viscometers fall short.

Here are five points to check when you look for an instrument to analyze the viscosity in your production:

☐ Measures the right metrics – the property that is important for quality. This measurement can be a single viscosity at one shear rate or a shear-thinning liquid’s viscosity curve.

☐ Measures at the right temperature (viscosity is highly temperature-dependent).

☐ No risk of human error. Only full automation can secure the highest precision.

☐ The sensor is easy to keep clean and does not contaminate the liquid production – and the sensor doesn’t prevent thorough cleaning of the pipe or tank in use.

☐ Communicates the measured data to the factory control system for logging and input for the process control loops.

Inline, On-line, At-line – or Somewhere Else?

The big difference is the time it takes.

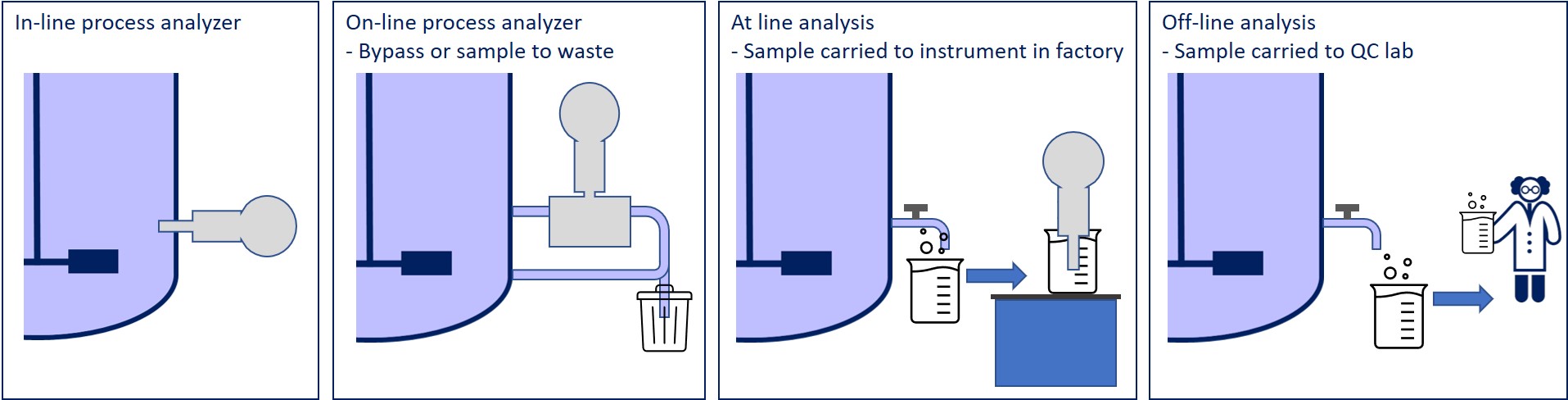

You can measure viscosity in many ways and at several points in your process.

However, only if the measurement is fully automatic and the data is available to the factory control system can it be useful for real process control. This type of measuring is reachable only by conducting “inline” and “on-line” measurements (see figure).

Forget the SOP – Just Measure!

“Our method is highly reproducible. We have documented this in a validation report … I think it was in 2003”.

Hmmm… people come and go, and newly trained operators fill their place. And even the best manual method is subject to manual errors.

With a fully automated analysis, you can eliminate human error. As a result, you improve the precision of your process. No more sample variation due to its handling before the analysis. No more “judgment.” No more risk of making a mistake when reading the scale on the instrument and noting a wrong number.

When measuring the paint’s viscosity, it makes a difference if the sample sits for 15 minutes or an hour waiting for the procedure. It makes a difference if the sample is (accidentally) shaken a bit before the measurement. Lastly, there is a temperature difference between measuring at the edge of a beaker while measuring the beaker’s center’s viscosity, where the temperature may be higher.

It is possible to control these factors by carefully following an SOP and by recurrent training of operators and procedures validation. All of which requires time and skill.

Only a fully automated analysis takes the human error out of the procedure.

RheoStream Ticks All the Boxes

If the liquid is non-Newtonian, there is no alternative to precise control of the shear rate. RheoStream does that.

RheoStream takes full control of the sample – temperature and shear rates. It even measures at multiple shear rates allowing for much more rigorous quality control.

There are no intruding parts into the product stream, so cleaning inside pipes and tanks is unaffected. Being fully automated, self-cleaning, and interfaced to the factory control system, RheoStream, acts as a sensor, providing the information needed for taking control of the process.