Let me guess: You are interested in optimizing the manufacturing process of a product that your company manufactures. And you have realized that online measurement of viscosity would be a great help in doing so.

In this article, you’ll understand more about RheoStream and if it’s the right choice for your company.

RheoStream is a Fully Automated Capillary Rheometer

RheoStream® is a capillary rheometer for real-time in-process measurement of viscosity, shear-thinning, and apparent yield stress in viscous non-Newtonian liquids.

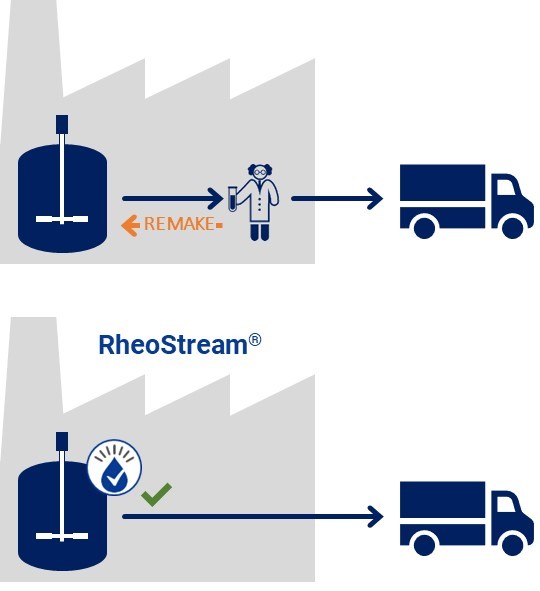

RheoStream is designed for installation directly onto a production line. Here, it will continuously measure the viscosity profile of your liquids. With new data, it becomes possible to control and adjust the manufacturing process, keeping the rheology on track. No product will be too thick or too thin.

The core of RheoStream is a capillary and a precision dosing pump. The pump pushes the liquid through the capillary at pre-set flow rates. The thicker the liquid or, the faster the flow, the larger is the pressure drop across the capillary. With the right calculations, RheoStream can convert the pressure drops and the flow into precise viscosity values across a range of shear rates.

The output from RheoStream is the viscosity at up to 4 pre-selected shear rates.

It could look lit this:

ThSome industries like to work with rheological models, like Bingham, Herschel-Bulkley, or Casson. Such models characterize the rheology profile by parameters obtained by fitting the measured data to the model. In that way, you get a measure of apparent yield stress, consistency index, etc. RheoStream can do that, too.

Read more about RheoStream here.

RheoStream will generally perform a full measurement every 1-2 minutes. The sample is sucked into RheoStream through an inlet tube and discarded to waste. The sample is only 5 ml.

Read more about the connections and installation below.

One more important feature that sets RheoStream apart is that it controls the liquid’s temperature in the capillary. Viscosity is highly dependent on temperature, so you need to ensure that the measurement occurs at the correct temperature, typically 20°C, 25°C, or 40°C. With RheoStream, you select the measuring temperature and the shear rates – the rest is automatic.

Is RheoStream the Right Choice for My Liquids?

Well, we hope so. But let us check:

RheoStream is designed to measure liquids that are homogeneous and without large particles. Particles up to ½ mm are OK. The liquids should not harden or dry when they are inside a closed system without air, and they should not stick to surfaces.

Moreover, liquids may be too thick or too thin. After all, the instrument pumps the liquid through a capillary, and if they are too thick, the pressure required is above the design limit. If liquids are very thin (water-like), the pressure drop across the capillary is too low to measure accurately.

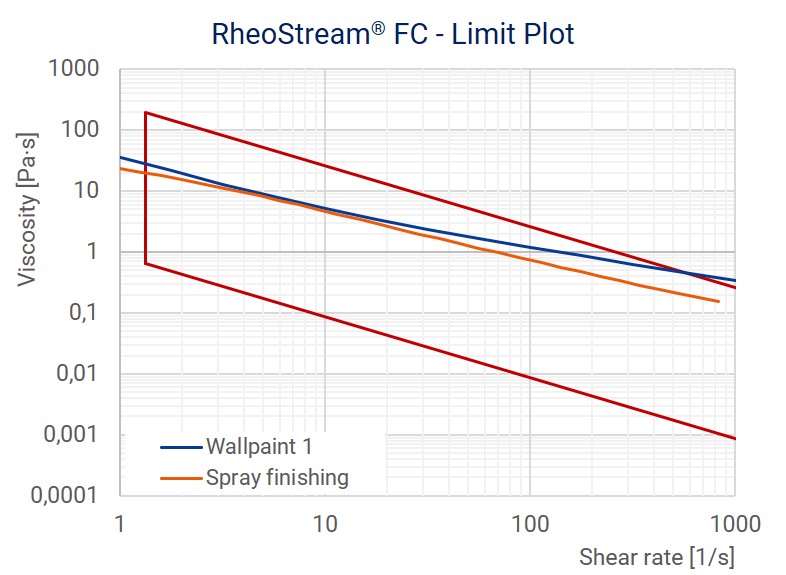

In practice, the application area can be illustrated like this:

This example shows that the Spray finish can be measured across its full shear rate range of RheoStream (1.5 – 1000 [1/s]).

The wall paint can be measured up to about 100 [1/s].

When you check your requirements using this chart, remember to define the shear rate range in which you wish to measure the viscosity.

So, bottom line, here are some of the industrial liquids for which RheoStream is the answer:

- Paints / Coatings

- Some adhesives (e.g., white wood glue)

- Liquid laundry and dishwashing detergents and fabric conditioners

- Liquid soaps and shampoo

- Lotions and some creams

Will RheoStream Fit in My Factory?

You will install RheoStream close to the process having the liquid to be measured. Very close, because in that way, the liquid flows quickly into the instrument, and you get up-to-date measurements. RheoStream can be installed on a pipe or a tank – we’ll cover the installation and interfacing details in an upcoming article.

RheoStream also needs to be connected to a cleaning liquid supply – this can be water for most products, or it can be a cleaning solution used in the factory. And the instrument needs power – 24V DC.

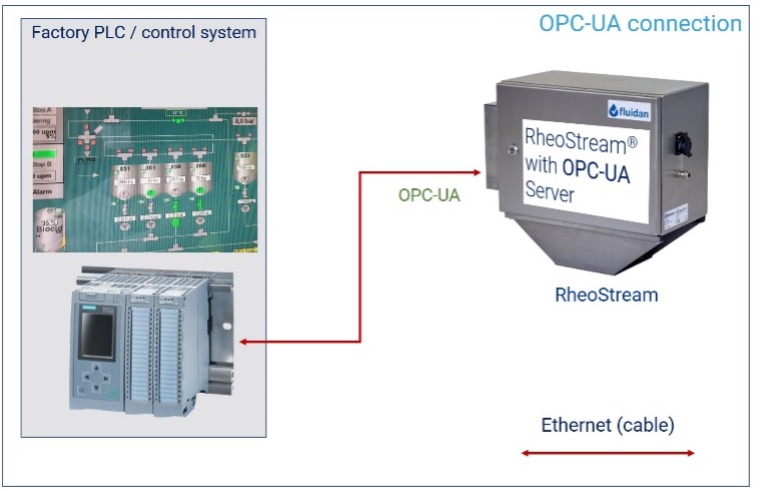

Next, RheoStream interfaces to the factory computer system. This pairing occurs via an ethernet cable. The interface can be entirely digital – using the OPC-UA protocol – or it can be a combined analog/digital signal with viscosity data transferred in a 4-20mA signal.

That’s it. If RheoStream is the right fit for your liquids production, and once you install it into your factory, you are ready to enter the new era of automated rheology control.