RheoStream Takes Control of the Sample

In-line viscosity sensors located directly in the product flow have a hard time giving good results. This is because the surrounding flow and temperature fluctuations directly influence the viscosity measured by the in-line sensor.

Once RheoStream has drawn a small product sample from the production, it takes complete control over the sample temperature and flow. This process is in deep contrast to in-line instruments that must do the measurements at the temperatures and flow-conditions dictated by the production equipment. Therefore, the viscosities measured by RheoStream are more precise and have smaller measurement-to-measurement-variation than in-line instruments.

RheoStream Controls the Sample Temperature

Liquids get thinner when heated. One everyday example is that gravy gets thicker as it cools off on the plate, among the beef and potatoes. This temperature dependence is seen in a whole range of commercial liquids and is an essential point in securing accurate quality control.

By raising the paint temperature by only 1°C, the viscosity may decrease up to 6%!

Such a viscosity variation is often unacceptable in Quality Control, and therefore it is critical with a precise temperature-control of the sample during a viscosity measurement.

As pointed out in the introduction, in-line viscosity-sensors are positioned inside the production equipment, such that the measurement is at the (often varying) production temperature.

RheoStream passes the sample through a heat-exchanger that ensures that the measurement temperature varies at most 0.1°C around a constant set-temperature! In that way, users of RheoStream need not worry about temperature effects – they are effectively ruled out.

Add in Shear Rate Control to Get Superior Precision

Once the temperature is rock steady, the fully automated measurements by RheoStream ensure a completely reproducible measuring procedure with a high level of shear rate control.

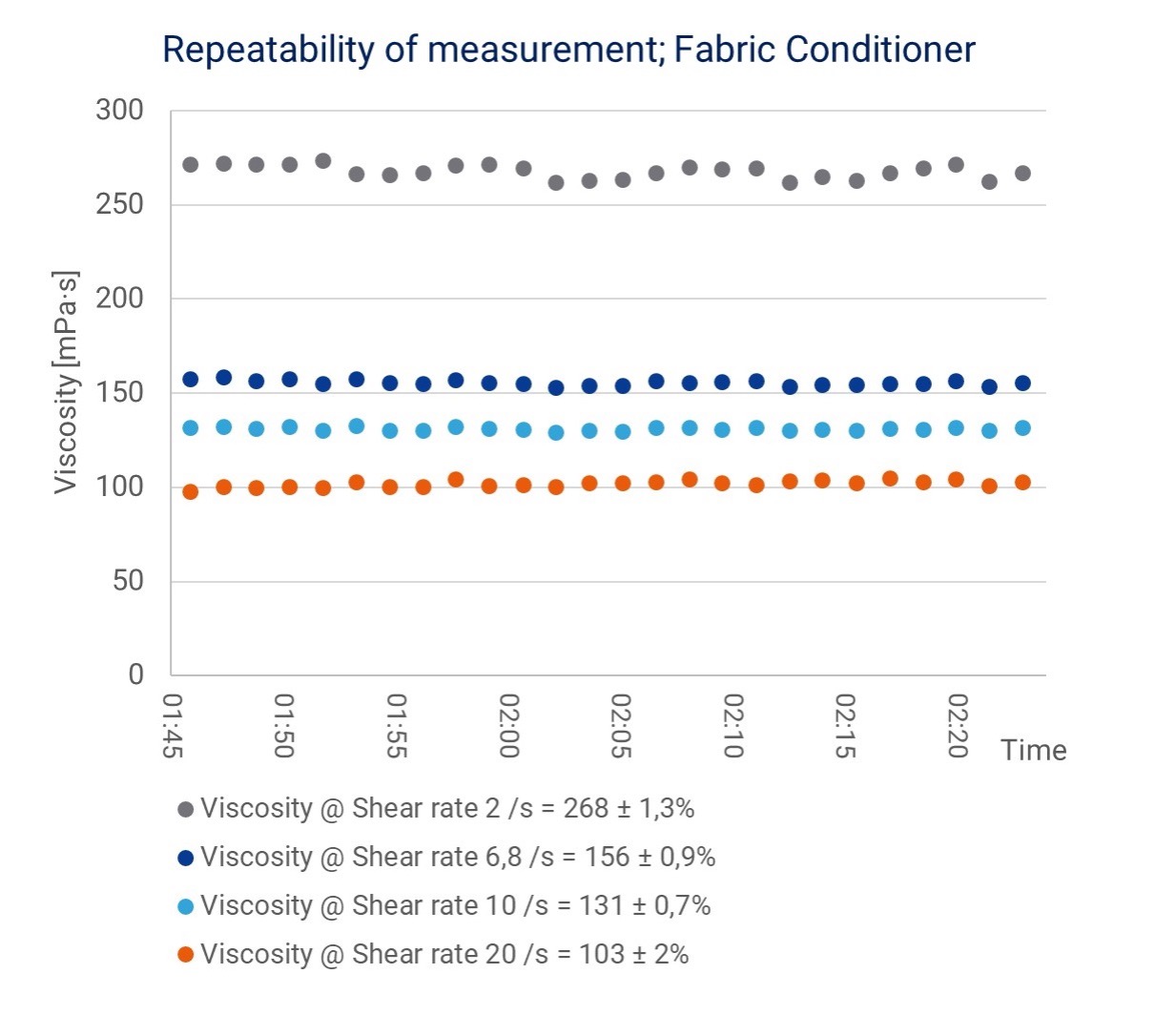

As covered in an earlier blog, Why Shear Rate Matters in Process Control, many commercial, viscous liquids become thinner when sheared. Therefore, viscosity measurements must be performed at well-defined shear rates [See our blog Different Types of Rheometers]. Precisely, therefore, RheoStream will automatically and simultaneously measure the viscosity at different customer-set shear rates.

All in all, the combined control of temperature and shear rate result in a superior precision that makes repeated measurements very reproducible.

The two graphs below show repeated measures by RheoStream on first a wall paint and then a household fabric conditioner. Both present the simultaneous measurements of the viscosity at different shear rates and underlines the excellent reproducibility of RheoStream measurements. (The legend indicates the uncertainties (CoV) of each series)

High Reproducibility Gives A More Profound Process Insight

The high reproducibility of RheoStream measurements is an excellent benefit for the customer. The reason is that the observed variations of the measured viscosities originate directly from actual product-variation over time. Observing these variations gives a unique insight into how all the other production-factors influence the viscosity during the production.

In that way, RheoStream gives you a new, detailed insight into the viscosity variations of your products over time. Use it to make the proper corrections to ensure a steady final product.

Below is an example of commercial RheoStream measurements at four different shear rates. It clearly shows the product’s time-variations during controlled changes in the production parameters (a change within each enumerated section). This installation and use of RheoStream continue to deliver valuable information for the given customer.

Summary

Many process control sensors benefit from being placed directly inside the process tubes or batch-tanks (in-line), but this does not include viscosity measurements. Viscosity changes considerably depending on the liquid temperature and the liquid’s shearing – two properties that vary inside the production equipment due to the change in production steps and mixers in tanks or during pumping of the liquid. This shift results in uncertain measurements of the process viscosities, which is not suitable for use as Quality Control.

RheoStream is a fully automatic on-line instrument, such that it sucks out a small product sample from the production and takes complete control over the sample temperature and flow. Controlling these two properties makes RheoStream measure viscosities with high precision and, therefore, smaller measurement-to-measurement-variation than in-line instruments.