Paint defects are a costly issue, causing unnecessary product waste, rework, and loss of time. There are paint finish quality issues (leveling, sagging, coverage, gloss, etc.) that can be prevented by correcting the paint viscosity during production. To get the quality right, paint manufacturers recognize the need to monitor viscosity during production. However, making viscosity measurement in the production has been challenging: The viscosity of paints varies under different conditions such as shear rate, temperature, etc., and only manual viscosity methods have been available.

RheoStream® FC is an automatic process viscosity analyzer, which can provide the paints’ viscosity curves during production at a controlled shear rate(s) and temperature.

With RheoStream, viscosity can be automatically controlled and adjusted.

Why Should Paint Viscosity Be Controlled?

In the paint industry, viscosity plays a critical role in determining the coating’s end-user performance. There are many end markets for paints and coatings, ranging from home builders to original equipment manufacturers. Moreover, the coatings are applied in different ways using a brush, roller, sprayer, or more high-tech application, and the viscosity must be optimal for the use.

Viscosity in the paint industry is essentially a measure of its thickness, which influences paint’s performance parameters such as coating film build, color match, voids, and chemical resistance. A coating must be stable during storage, easy to apply, and ideally, the final surface finish should be smooth and drip-free. Correct paint viscosity is, therefore, the key to good paint quality. A change in viscosity can indicate solvent loss or other quality problems.

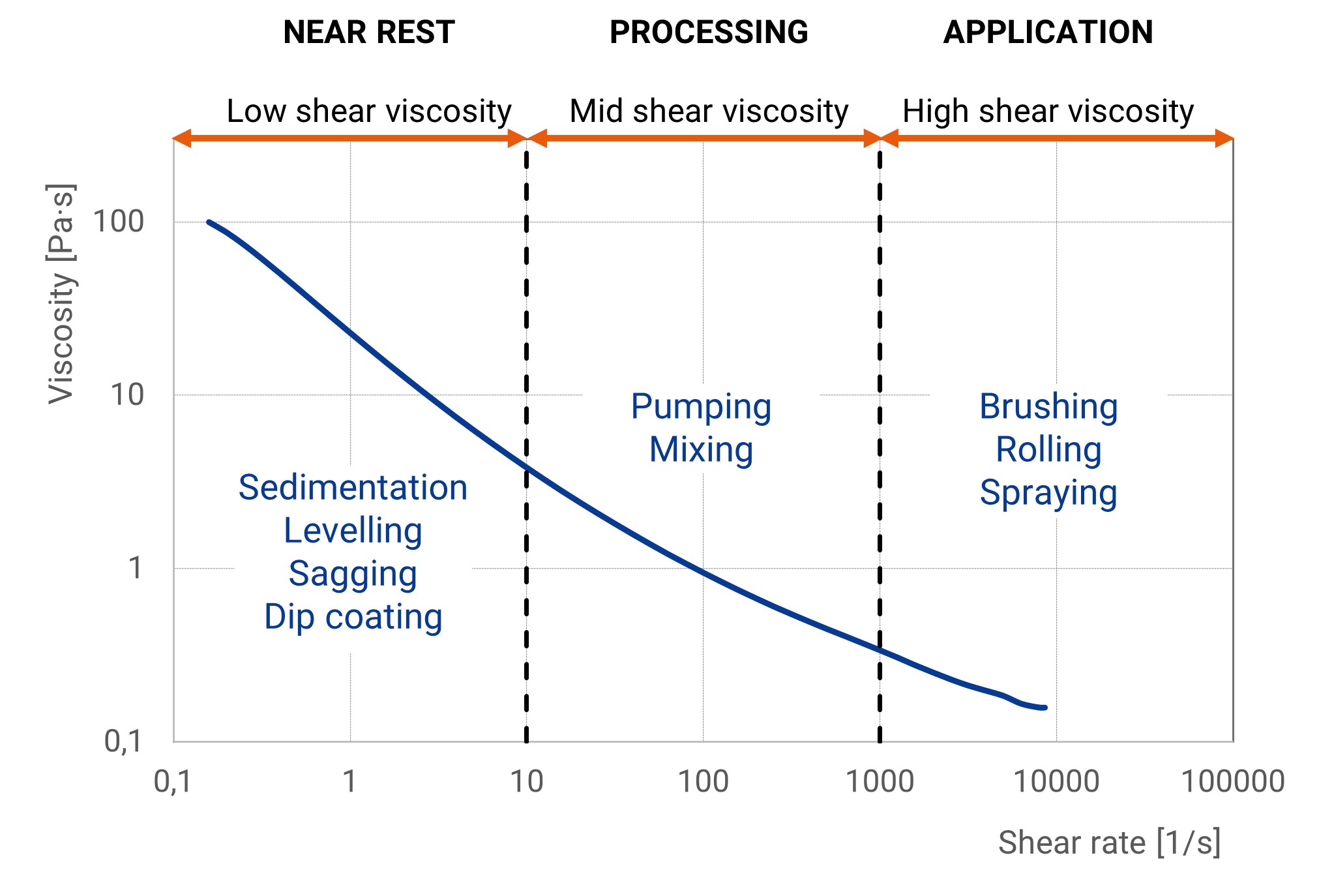

The viscosity of paints can change under different conditions. During processing and application, paints are subjected to various shear regimes [Read about shear rates]. For example, in the production process, paint is pumped around the plant, subjecting it to moderate to high shear, whereas storage and transportation are low-shear processes. An application can vary from moderate (dipping) to high shear (roller coating, spraying) – see the illustration below.

In the low shear regions (< 10 [1/s]), paints are expected to have high, solid-like viscosity to prevent phase separation and sedimentation. During production (10 – 1000 [1/s]), the paint is expected to have a medium viscosity such that it is easy for pumping, mixing, or stirring. During application (> 1000 [1/s]), the paint must be thin enough such that it is easy to apply by brushing, rolling, etc.

Common paint defects that may arise due to viscosity include:

- Sagging

- Poor Levelling

- Dripping

- Sedimentation

- Poor Coverage

- Poor flow

Process Challenges For Viscosity Measurements

Benefits Of Using RheoStream® FC In Production

RheoStream is a process viscosity analyzer that can continuously monitor viscosity in near-real-time during paint production. A process viscosity analyzer enables quality control of the intermediate or homogenized paint and ensures the finished product’s quality.

Moreover, continuous monitoring of process viscosity can quickly identify and correct errors during the production process and eliminate the need to make decisions based on intermittent “snapshot” data acquired from periodic sampling by laboratory viscometers. If a problem with viscosity is detected early, the number of batches that need to be modified can be reduced. The production capacity can be increased, and any costs towards scrapping of products can be reduced.

RheoStream helps to detect any paint batches that are off-specification in production by

- Providing automatic, continuous, near-real-time process viscosity measurements

- Eliminating variations in sample taking and handling

- Detecting even small changes in viscosity

Additional benefits:

- High repeatability of viscosity measurements (typical precision < 2%)

- Controlled temperature for measurements

- Controlled shear rate(s) for measurements

- Low maintenance

- Easy installation

- Fully automatic cleaning